You Can Build Your Own Switches ! !

Richard (Dick) Reichard

First let me introduce myself. My name is Dick (R. L.) Reichard and I am a retired Mechanical Engineer. My life long hobby is electric trains. I collect Marx, Lionel (O & O27) and AF-O gauge trains but I also have K-Line and MTH trains.

I have had several layouts over the years and switches have been one of the operational problems. I have a lot of Marx and Lionel locos and rolling stock. In the past manufacturers of switches (sorry to say) missed the boat when it came to making switches. Some Marx locos will not pass thru Lionel switches and vise-versa regardless of other features the switch may have. The switch manufacturers should have concentrated on being able to pass everyone’s equipment thru the switch. This could have meant more sales dollars for one or all. Durability of each manufacturer’s switches has never been an issue as far as I know.

I stopped using Lionel switches with a mix of sectional track some years ago and resorted to Marx Metal switches along with Gargraves track for better electrical conditions. The reason being of course is Marx locomotives. But it restricted running the Lionel equipment. Oh, I did run Lionel but very carefully thru the Marx switches.

Shortly after retiring, I analyzed tracking of troubling locomotives and rolling stock thru Marx switches and found a simple solution. Add a filler strip between the pivoting rails but it had to allow passage of the Marx flange gear locos in both directions and be an easy addition to the existing switch. Then shape a piece of plastic (?” thick.) with the clearances and mount it between the pivoting rails with double-faced foam tape, keeping it about 1/32” below the rails. It works by keeping the roller pickups of Lionel and others from dropping between the pivoting rails. It also has some noise reduction benefits. You can also add pins into the center rails (at the exit sides), closing the gap between the center rails and pivoting rails (a good place to snag pickups on if gap is too wide). Also you can bend them parallel to the pivoting rails if a little long.

I have always been dissatisfied with the 45° switches and having the switch machine on the wrong side of the switch along with ending up with unwanted “s” curves, when I began to create my layouts. No one that I ever found made a switch less than 45° except Lionel O72, Gargraves and the custom switch builders ($$).

I began to research all the books and magazines concerning 3 rail switch building that I could find. It soon became apparent everything was very complex and followed 2 rail design with very little info on 3 rail switches. Hey! These trains are toys not scale models – lets keep it simple. In the past I modified Marx switches by hacking off about 13° of the curved portion of the switch but that was a lot of work and to me it looked like a hack job.

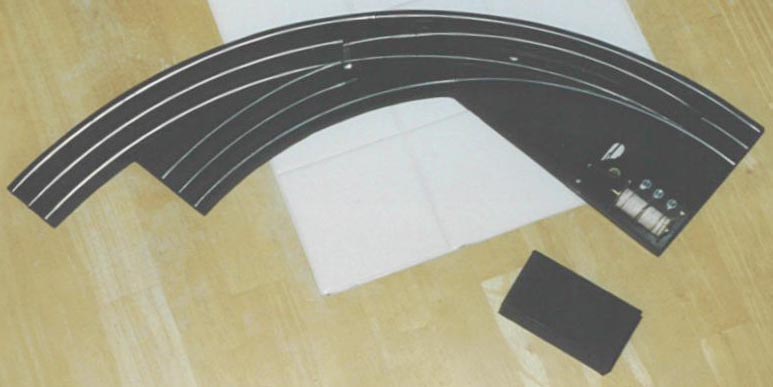

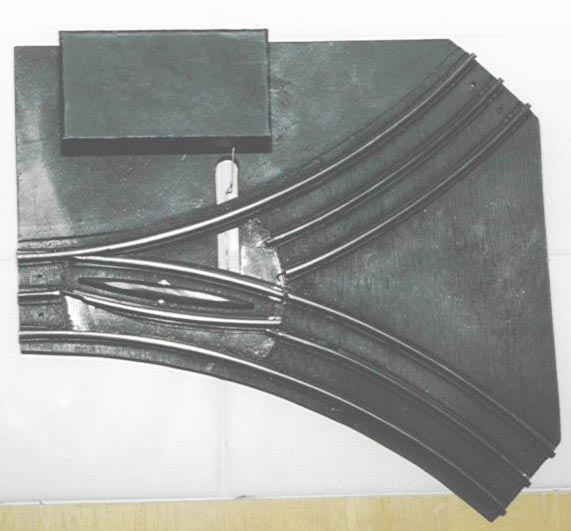

I decided to attempt to build a switch within the length of O27 straight track, having a turn out center spacing of 2” and I would use the track I had available. I decided to use the Marx Metal switch design with the pivoting rails and a closed frog (Marx has an open frog). The 2” spacing would allow a single crossover with 4” spacing.

I am fortunate to have a CAD program available to me and began to make some sketches as to what I would need. Very quickly I needed to know all the dimensions of the track and found there are differences between manufacturers and their techniques. I was able to obtain all the dimensional information and proceed to make a full scale drawing. I used this drawing as a template to start the building process. I took me about 2 to 3 weeks to complete my first switch (manual operated) to prove the assembly methods, I did make a few errors along the way but the rewards were great. It worked and I proceeded to make 2 pair of the 15° O27 switches along with switch machines (patterned after the Marx switch machine only with a spring loaded toggle locking device). These reside on my layout now and I have not had any problems with them.

I proceeded to fabricate O27 wyes both open and closed frogs along with an O27/O34 curved switch using the same building techniques. I followed these up with a pair of 15° O31 switches and all have proved to be very functional with no problems. I also designed a 1 to 4 terminal or yard switch set for O27, O31 and “S” Gauge. I built the O27 1 to 4 and it works and will have its place on the layout.

There are a few unique things about these switches which are as follows:

1. Your choice for the switch machine location. (left, right, under)

2. Can be serviced if necessary from the top.

3. All switches regardless of gauge have ½ “ throw

4. They can be made non-derailing if the builder desires.

5. All the 15° switches have 2 to 2.1” turnout spacing

6. There is only one (1) fastener required per switch

7. The rails are held in place via an epoxy adhesive.

I created a “Switch Building Manual” for Marx trains and presented it at the 2001 Marx Convention in Wheeling, WV. A lot of interest was generated and I have proceeded to do Manuals for Lionel O gauge (O31, O42, O54, O72), Lionel O27 gauge (O27, O42, O54) and AF “S” gauge. All of the gauges have a specialty manual devoted to the curved and 1 to 4 switches except the “S” gauge which is all in one manual.

As an end I have tried to make the switches as easily constructed as possible with out being complex. They are constructed from existing new or used track and all other materials are easily available via hobby shops, hardware, lumber and electronic supply stores.

All of the manuals come complete with material and suggested tool list, complete assembly instructions (with pictures) and full scale templates. The templates eliminate the need for layout work. The templates are dimensioned for referencing but very little measuring is required. These switches are not difficult to build. Take your time and it will be rewarding.

I have discovered via these switches that the manufacturers of locomotives and rolling stock indicate the minimum operating diameter to be somewhat false, because they evidently base their findings or calculations on operating on a full circle. Some of these locomotives will operate very nicely on 15° of arc on O27 track. Possibly they could change it to a table indicating the maximum degree of arc for a given track diameter.

I hope these manuals will add another dimension to layout building for the WORLDS GREATEST HOBBY!

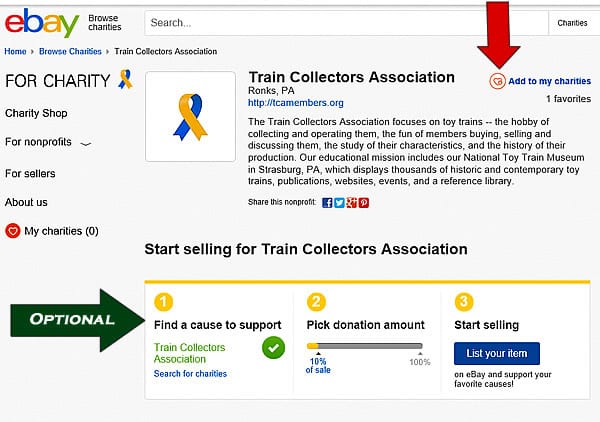

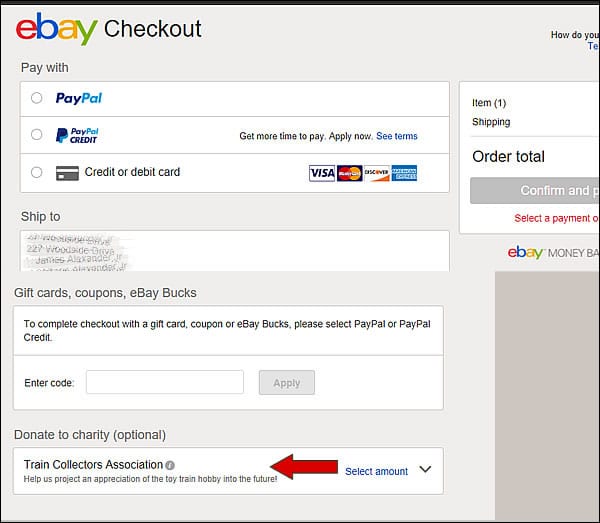

Click here for the Pricing and Ordering form. (Rev. 9/2013)

ps: I am working on double crossovers for all the styles, along with Standard gauge switches as soon as I can assemble the required dimensions. I have under construction a 5 rail combination O gauge/Standard gauge switch but I need to prove out the design and switch machine function.