How An Old Hot Dog Wrapper Led To Decals For A Freight Car

By Mike Marmer, TCA # 92-35192Summer 2018

One of my many interests in life, ever since I was a kid, was baseball, along with, of course, model trains.

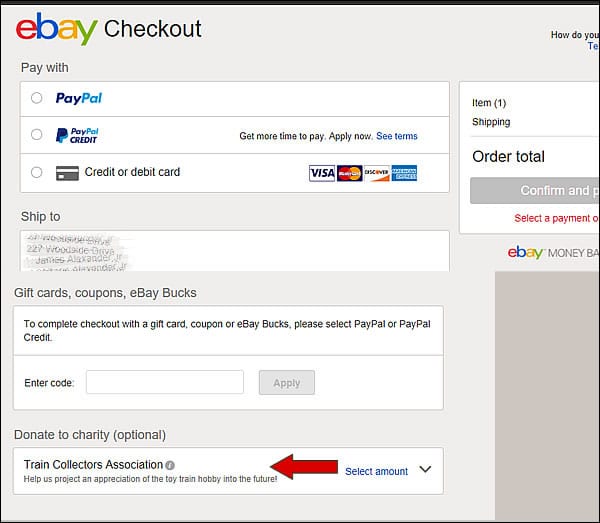

I was heartbroken as a 17 year old in 1971, when a second baseball team left for another town. A couple of years ago, when searching “Washington Senators Baseball” I saw this unused Briggs Hot Dog wrapper from Griffith Stadium in the 1950s. I had to buy it! Not only did it relate to the Washington baseball club, but it’s a brand of hot dog I remember! These memories stemmed from growing up in the 1960s and in my career as a food product salesman to restaurants in the Washington, D.C. area. So, it became a double tie-in for me with this one hot dog wrapper.

So now I have this hot dog wrapper and I thought, the graphics on the wrapper would make for a great refrigerator car for my layout. Now I had to come up with someone who could make me decals from this hot dog wrapper, as I have no expertise in doing anything like this. And then, I needed a car to put the decals on.

I was looking in an old S Helper Service catalog and they showed an undecorated refrigerator car, with wood slots, painted yellow with a brown roof. The ladder and door trim were painted black, so that was good. But, as luck would have it, the company went out of business, so there was no new stock being put out by S Helper to suppliers.

So I had to search for this car and that, I knew, was not going to be easy.

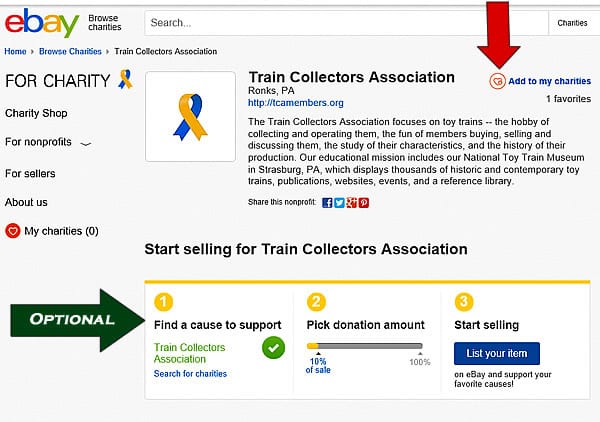

After several years of looking at train shows and on eBay, a “new in box” car came up for bid on eBay. I was not going to lose this car and for sure, I won. So the first part of making this car a reality was done.

And now it was time to find someone who I could pay for making decals from the graphics on the hot dog wrapper. This was also not going to be easy!

I contacted a few commercial model train decal companies about making custom decals, as they did custom work. However, I only needed a couple of sets and that was way below the required number of sets. The cost would have been very high expense to me just for meeting that requirement. And I still could not make the decals on my own, since again, I did not have the expertise or the proper printing program to do so.

So, in December of 2018, while on eBay (probably looking at American Flyer trains, since I am a collector) I saw a custom-made American Flyer car. The work on this car, the repainting of it and the decals where very well done, very professional, and there was only one car being sold. It appeared most likely only one set of decals was printed out, by a guy named Chuck, who did this type of work on the side.

I contacted him, told him my story in trying to get decals made for one car, and how very difficult it had been finding someone who would do this for me. Chuck replied back, very nicely, and gave me his email address. He asked me to send a copy of the hot dog wrapper.

I sent him a scan of the wrapper, and he wrote back saying the image was too distorted. He needed a better quality for a good set of decals to be made and he was very sorry that he could not help.

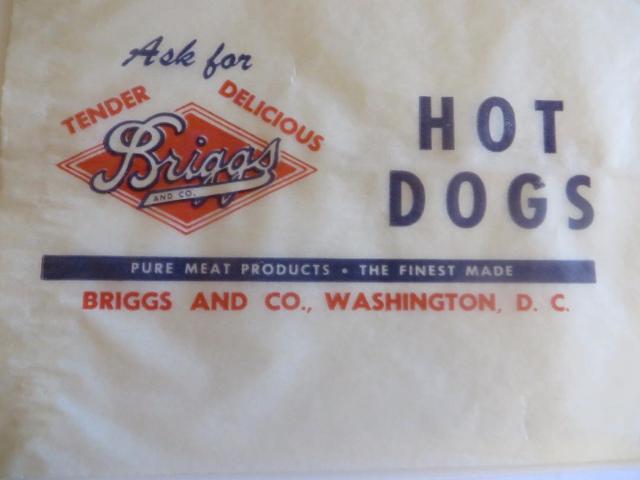

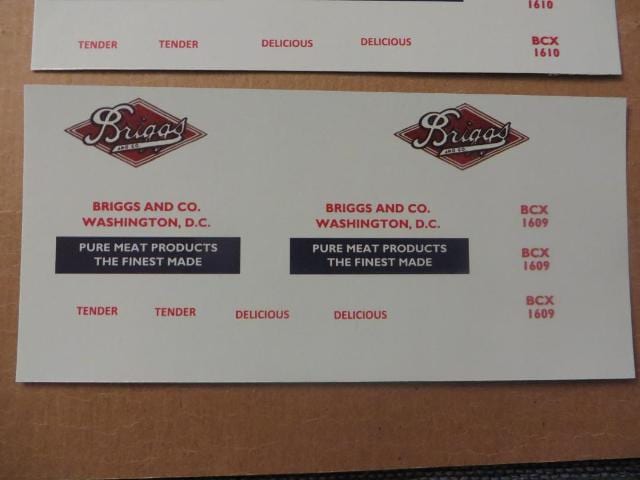

Not discouraged, I took a photograph of the hot dog wrapper, sent it, and asked if the photograph was of a sufficiently better quality to be used in making the decals. He wrote back saying that the photo was better, and, better still, that this is going to be a challenge that he wanted to take on. Maybe he meant that the photo was still not as good for making the decals, but with his computer programs, he might be able to get something made. I gave him the measurements on where the decals would go, taking into the account the area for the doors and ladders on the car, the space between them, and then the space from the roof to the floor.

After a week, as he was out of town for work, he sent me an email with an attachment of how the decals would look with the size he had worked them down to. They looked great! I printed the attachment and then cut the “decal” out, making a mock up on the car. They fit the area perfectly.

So Chuck proceeded to make me two sets of decals and I told him I needed to know how much I owed him for these and where to send the check. He would not take any money from me, as he appreciated my desire to have this car made and how I was an S train enthusiast.

The decals came in December and they where perfect. I could not thank this man enough. Since Chuck is a president of a college, I made a very nice donation to the school in his name.

But then tragedy hit me. In mid January my left wrist was in great pain. I had torn a muscle and needed surgery, which was surgery number 39 on me over the years. So wrist and thumb joint surgery was done on January 30. Not good for working on the details of this project! So having my hand in a cast for a month, then a month of PT, I was finally ready to take on the task of putting the decals on the car in early April.

I have decaled a couple of box cars in the past, but it has been awhile. Chuck had typed up instructions for me to follow. When cutting out the decals from the sheet, you cut as close to the image as you can to be put on the car. In using a very fine pair of scissors, I was very careful in cutting off as much of the clear part of the decal around the image made.

And then, you soak the cut decal in water, and then apply. I had my ruler with me, to center the decals on the car, side to side, top to bottom. But one of the decals, when cutting so close to the image, I, somehow, snipped into the image part of the decal. So that was not good. Thankfully Chuck had made two sets of decals, so I did have some extra decals for the car; in case something happened when cutting them out.

I got one side of the car completely done, then applied Solvaset to the decals. This solution hides the edge of the decals and gets the decals to set snug on the car. It looked pretty good! So I let the decals dry and then I repeated this process with the other side.

Once the other side was done and dry, I sprayed two light coats of Testor’s Dullcote to the car for the protection of decals and let it dry.

Now the car is done and is on the layout. It is running with a line of freight cars, loaded up with all kinds of meat products. These cars of hot dogs and half smokes are to be delivered to J. Lechner’s Food Co. JL’s is the sole food distributor to S Helper Field, the home of the D&K RR Pinheads baseball team, low class D, Dingburg, Maryland. At the field they will be served up nice and hot at David’s Eats, the concessionaire for the ballpark. By the way, the Briggs Company of Washington, D.C. did invent the Half Smoke!

And now I have a really sharp looking S Helper Service refrigerator car, with the custom made decals by Chuck, out of Oregon. It took some time, but in the end, it was worth the wait for this to finally happen (in my lifetime!)