Christmas Enablers

By Bill Fuller

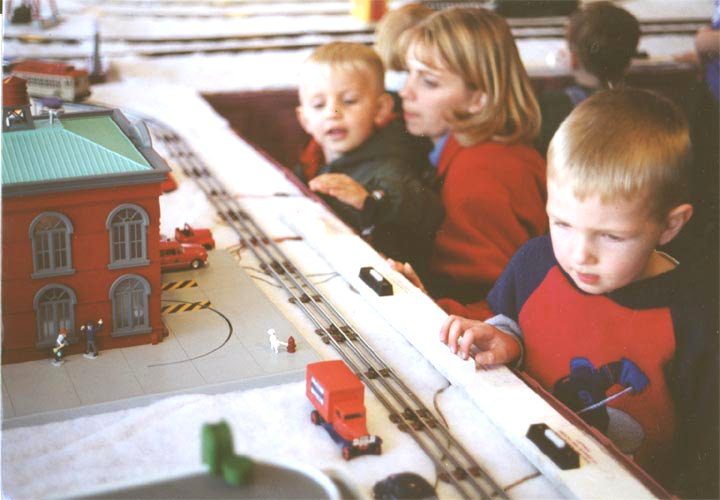

Santa Claus is okay, but Christmas just can’t come unless there are trains running, and each year Bill Fuller and Jim Seward make sure that Christmas will come to Spearfish, South Dakota. When the “Festival in the Snow” arts and crafts fair opens in the Holiday Inn Convention Center on the first weekend in December, the trains will be running.

The Inn provides the tables, which Jim and Bill cover with foam carpet padding and white quilt batting. Sectional track is laid on top of the batting, trusting in friction to prevent unwanted rail separation. Department 56 ceramic buildings fill up empty spaces between the tracks, while a variety of Lionel and MTH operating accessories are aligned near the edges of the layout where their performances can be fully appreciated by visitors. Since neither Bill nor Jim wishes to alienate the Convention Center staff by returning their tables drilled full of holes, wires to tracks and accessories are laid between the layer of carpet padding and the batting.

With four extended ovals of 072 or greater radius for freight and passenger trains, an 027 oval hosting a handcar, and a twisting, bumper-ended line with a Christmas trolley car, the layout entertains visitors with six active tracks. Viewers don’t even mind when a scale UP steamer has to be sidetracked for emergency repairs to a circuit board in the tender and an Alaskan Railroad scale F-3 is pressed into duty to haul the UP passengers home for Christmas.

To enable visitors to interact with the layout and get a little hands-on operating experience, Bill and Jim want to provide push buttons for operation of accessories but are confronted by those borrowed tables which can’t be mutilated with screws or wire holes. They solve the problem by cutting two planks about three inches wide and three feet long, painting them white to complement the “snow” batting, and screwing six surface-mount doorbell buttons to each plank, spacing them as far apart as possible to minimize crowding and bumped elbows among operators. Wires to the doorbell buttons run through holes drilled in the planks and are then threaded between the batting and the carpet pad. Computer-printed labels taped above each button identify which objects are controlled and instruct operators to “press and release” or “press and hold”-although in their excitement, few people bother to look at the labels.

The planks with their label buttons are merely laid on top along the outer edges of the tables. The wires tucked underneath the batting provide sufficient friction that nothing else is needed to hold the boards in place. Button-operated accessories include a Lionel crossing gate, gateman, banjo signal, animated billboard, and Lionel Pipe Company forklift loading platform. In addition, an MTH firehouse, service station, and car wash are button-activated. The $2 doorbell buttons from ACE Hardware have withstood hundreds of pushes; some not too gentle, and are ready to provide more interaction each year.

What do Bill and Jim get in return for building, operating, and then dismantling this set-up every December? Look at the faces in the photographs accompanying this story. The rapt expressions of amusement, amazement and excitement are payment enough for all the effort!