Articulating Some Articulated Facts

By Robert S. Butler

A brief scan of any current magazine or catalog devoted to toy trains reveals a mind-boggling array of choices with respect to steam locomotive power. One version in particular-the articulated- cannot fail to capture the eye of even the most hard-core diesel enthusiast. It is difficult to believe that barely 15 years ago, the thought of an articulated locomotive on a 3-rail right-of-way was something reserved for wild flights of fancy. In the years since Williams first offered a three-rail model of the Union Pacific Challenger, numerous manufacturers have provided a variety of articulated locomotives for the three rail high iron. While the toy catalogs are long on pictures and superlatives describing the offered models they are very short on providing any information concerning the why of the existence of this kind of motive power.

Early History

Technically, an articulated locomotive is any locomotive whose wheel base in not rigid. Thus, the Shay, Heisler, Climax, Meyer, Meyer-Kitson, Fairlie, Garratt, Mason-Fairlie, and Mallet are all classed as articulated locomotives. This article will limit its focus to the origin and development of the Mallet and its derivatives.

While the Rainhill trials of 1829 gave a major boost to the development of the railway locomotive (Robert Stephenson’s Rocket was the only engine to fulfill the terms of the competition and win the prize of 500 pounds) the focus of that trial was on rigid frame locomotives. Early rail traffic was light and, consequently, early engines could be built small with rigid frames. Because the traffic and the locomotives were small, the roads were light in rail and bridge construction and sharp in radius of curvature. By 1851 the increase in traffic generated a need for locomotives with increased pulling power. In order to increase pulling power it is necessary to increase adhesive weight. In order to increase adhesive weight the loads on the fixed driving axles have to be increased.

Unfortunately, the loads on the fixed axles could only be increased to the load limit of the bridges and right-of-way. It is, of course, possible to increase adhesion and stay under the right-of-way load limit by increasing the number of drivers. However, as the number of drivers increase the length of the locomotive also increases and when the rigid wheelbase becomes too long, the locomotive cannot get around curves. In short, by 1851 locomotive builders were running into size and weight limits set by the early infrastructure of the railroads themselves. It was this conflict between traffic demands and infrastructure that gave rise to the articulated locomotive.

Like the rigid frame, the articulated too benefited from a competition-the Semmering Contest of 1851. The Semmering railroad crossed the ice covered Nordic Alps and the limitations due to grade and curve was such that it appeared that it was no longer possible to increase tonnage moved on the Semmering with rigid frame engines. There were four entries in the contest: The “Bavaria” which used chains for power transmission, the “Seraing” which was a precursor of the Fairlie type of locomotive, the “Vindobona” which had four coupled axles and was not articulated, and the “Wiener-Neustadt” which had two trucks and coupling bars. All of the locomotives met the requirements of the contest and all were failures. However the ice, as it were, was broken and people began to consider articulation as a type of locomotive construction.

The Mallet

From 1851 to 1884 a number of inventors and manufactures in the U.S. and elsewhere worked to develop the articulated locomotive. The first really successful articulated was proposed by Anatole Mallet in 1877. In 1884 he took out French patent 162,876 for a system of articulated locomotives whose focus was not on increased adhesion and radius of curvature limitations but rather on the then vexing problem of the day-the utilization of compounded steam.

It had long been evident that steam that was exhausted to the stack after a single use in the cylinders was a waste of energy. To this end numerous attempts had been made to take advantage of the low-pressure steam exhausted from the initial set of high-pressure cylinders in order to extract additional work. Mallet’s solution was to have four steam chests driving two sets of wheels. The set nearest the cab were rigidly attached to the frame and the high-pressure (H.P.) steam passed directly from the boiler into a first set of small diameter cylinders. The low-pressure (L.P.) steam was then exhausted through a flexible tube to a set of larger diameter cylinders which powered a second set of drivers mounted on a movable frame. The most important part of Mallet’s patent was the fact that he had successfully overcome the problem of moving steam through a flexible steam tube using a combination of sliding and universal joints to couple the tube to the main boiler.

The use of high and low-pressure steam in this fashion gave the Mallet locomotive a built in anti-slipping feature. If the rear wheels began to slip the high-pressure steam would transfer to the low-pressure cylinders faster than it could be used. The resulting back pressure against the H.P. cylinders would stop the wheel slippage. In a similar fashion, if the front wheels began to slip the steam pressure to the front cylinders would drop until the pressure was in equilibrium and wheel slippage would again cease.

U.S. Articulateds

European roads began to run Mallets in 1888. The first Mallet on U.S. roads was “Old Maude”, an 0-6-6-0 Mallet built by ALCO for the B&O in 1906. The B&O 0-6-6-0 was closely followed in 1907 by 0-8-8-0 camelbacks which ALCO built for the Erie railroad. The early success of these engines encouraged others and engines and wheel arrangements proliferated. By 1911 Baldwin and ALCO had produced 539 Mallets. In 1911 the most popular selling wheel arrangement was the 2-6-6-2 with 340 units made for all railroads. The 2-8-8-2, which would ultimately become the most popular wheel arrangement of the 1930’s, was a distant second with only 63 units produced.

As with any successful idea impractical modifications abounded. Two of the more interesting ones focused on the problems of tractive effort and boiler overhang.

Tractive Effort

During the second decade of the 20th century many railroads were enamored of tractive effort. This focus on the maximum tonnage that could be moved by a single locomotive gave rise to some truly gargantuan Mallets. The largest of these were the 2-10-10-2’s built for the Virginian in 1918. They were so wide that they could not be delivered fully assembled. They boasted 28” H.P. cylinders and 50” L.P. cylinders. The inertia of the large low-pressure pistons limited the top speed to around 15 miles per hour. In 1914 the Erie took the next logical step in tractive effort and ordered up a Triplex. The Virginian railroad followed suit in 1916. These Mallets had high-pressure cylinders near the center of the locomotive. One set of cylinders exhausted backward to the rear set of L.P. cylinders and the other exhausted to the forward set. The problem with all of these sets of cylinders was that they required a tremendous amount of steam. A high-speed 4-8-4 locomotive needs about 20 to 30 square feet of grate area for each drive axle. The Erie Triplex could muster a little more than 7. Thus, it is fair to say that the Triplex suffered from exhaustion-too little steam for too many pistons. This also meant that only half the exhaust steam went up the stack consequently the draft for the firebox was extremely poor. The Virginian Triplex could manage about 5 miles an hour and apparently never made a single successful trip. In spite of this, the mania for reusing low-pressure steam drove the engineering teams at Baldwin and other builders to put forth design proposals for Quadruplexes and Quintuplexes despite the fact that a single revolution of the drivers in such machines would suck every last molecule of steam out of a boiler. Needless to say, an engine without steam in the boiler is not going to go very far.

Boiler Overhang

On real railroads, just like on toy railroads, when a Mallet rounds a curve the boiler will overhang the right-of-way. The tighter the curve, the more the overhang and the more the center of gravity is displaced to the outside. An overhanging boiler may come in contact with roadside obstructions such as station platforms, signal posts, canyon walls and the like. And, just as on three rail empires, overhang makes coupling difficult on curves. Concern for this problem of Mallet boilers gave rise to flexible boilers. In 1910 Baldwin built two such 2-6-6-2 Mallets for the Santa Fe. As might be expected, the maintenance problems associated with all of the flexible couplings for boiler tubes and steam feed drastically outweighed the problems associated with boiler overhang

Single Expansion Articulateds

Mallets with their distinctive H.P./L.P. cylinder configurations dominated the U.S. articulated scene until the mid 1920’s. By then a combination of improved steam joint sealing and super heating permitted the use of high-pressure steam in all four cylinders. These developments gave rise to the high-pressure single expansion articulated locomotive with same diameter cylinders for both sets of powered drivers. With superheated steam and high-pressure cylinders powering all wheels these engines proved to be useful for high-speed freight and passenger runs.

Three Rail Power

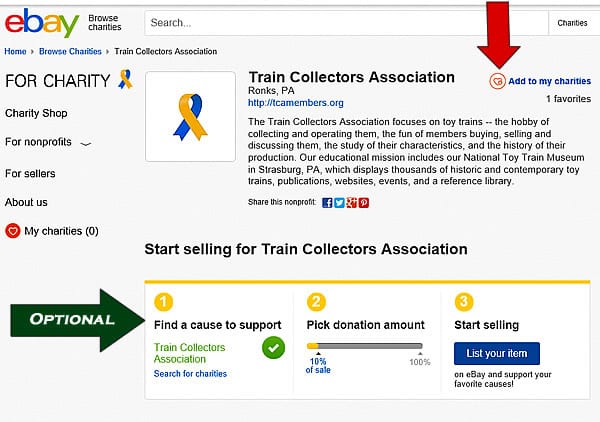

While Williams was the first to import articulated locomotives for the three-rail market they were quickly joined by others. Numerous wheel arrangements have been offered since the first UP Challenger came to market. The following list isn’t exhaustive but it does give some idea of the Mallets and Single Expansion Articulateds that have been produced. For purposes of identification Mallet will refer to engines with H.P. and L.P. cylinders and Single will refer to engines with only H.P. cylinders.

Railroad Designation Type Wheel Arrangement Toy Manufacturer

CSR&E #7 Mallet 2-6-6-2 3rd Rail

C&O H-6 Mallet 2-6-6-2 Right-Of-Way

B&O KK-2 Mallet 2-6-6-2 Right-Of-Way

N&W Class A Single 2-6-6-4 Williams, MTH, Lionel

UP Challenger Single 4-6-6-4 Williams, MTH, Lionel

UP, D&H Early Challenger Single 4-6-6-4 3rd Rail

D&RGW Challenger Single 4-6-6-4 3rd Rail, MTH

Clinchfield Challenger Single 4-6-6-4 3rd Rail, MTH

C&O Allegheny Single 2-6-6-6 Right-Of-Way, MTH, Lionel

Erie L-1 Mallet 0-8-8-0 3rd Rail

GN Mallet 2-8-8-0 Right-Of-Way

UP Mallet 2-8-8-0 Right-Of-Way

B&O Mallet 2-8-8-0 Right-Of-Way

B&O Y-3 Mallet 2-8-8-2 MTH

N&W Y-6b Mallet 2-8-8-2 MTH

Santa Fe Mallet 2-8-8-2 Lionel

Virginian Mallet 2-8-8-2 Lionel

GN R2 Single 2-8-8-2 Weaver

SP Cab Forward Single 2-8-8-4 Williams

UP Big Boy Single 4-8-8-4 Everyone and Their Grandmother

Although not every wheel arrangement has been made for three rail, the offerings that have been made cover almost the entire history of articulated locomotives in the U.S. In fact, with the introduction of the Erie L-1, 3rd Rail has made it possible for an operator to do something that no rail museum can do-own an example of the first and the last of these locomotives. As mentioned above, Erie’s L-1’s were produced just one year after the introduction of the first U.S. articulated. Unfortunately, none were saved for preservation.

The last steam engines built by Baldwin in 1949 (C&O class H-6’s) were not modern superpower locomotives but old fashioned Mallet compounds built for use on branch line coal routes. Right-Of-Way made a model of this type and numbered it #1302. The last H-6 off the assembly line was #1309. She was spared the cutting torch and is preserved at the B&O Railroad Museum in Baltimore, Maryland.

Sources:

1. Conrad-The Steam Locomotive Directory of North American

2. Huxtable-Classic North American Steam

3. Le Massena-Biggest of the Big-Railroad History-Spring 2001

4. Model Railroader-Prototype Plans-August 1967

5. Wiener-Articulated Locomotives